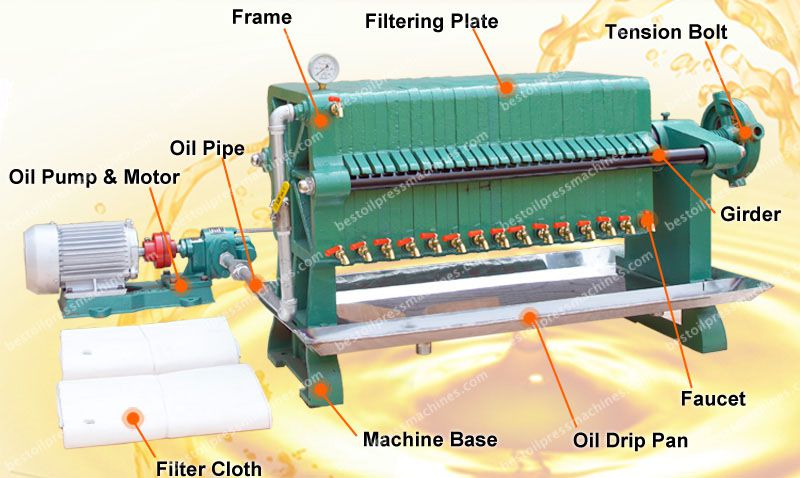

The plate and frame filter design is the standard in basic process depth filtration in applications across various industries including pharmaceutical chemical cosmetic food beverage plate and frame filter presses provide the lowest cost of filtration per unit of fluid processed.

Plate and frame filter setup.

Plate and frame filters.

Filter presses have been the focus of met chem manufacturing for many years.

A hydraulic unit allows the watertightness between the plates at the surface of the joints.

The filter is divided into three functional units.

The simplicity of the filter press means there is little maintenance work that is needed to be done to the press.

Gw kent offers multiple plate and frame filter system setups to meet the needs of your commercial brewery no matter what size.

Scott laboratories offers filter sheets and modules for depth filtration as well as cartridge filters for depth and absolute filtrations.

Becopad filter sheets 40 x 40 cm.

The plates determine a watertight volume in which is pumped the pressurized sludge.

Frame in aisi 304 stainless steel equipped with four pivoting wheels two of which equipped.

By adjusting the pressure regulator 13 set the pressure to about 4 psi 0 3 bar maintain this pressure for 10 15 sec.

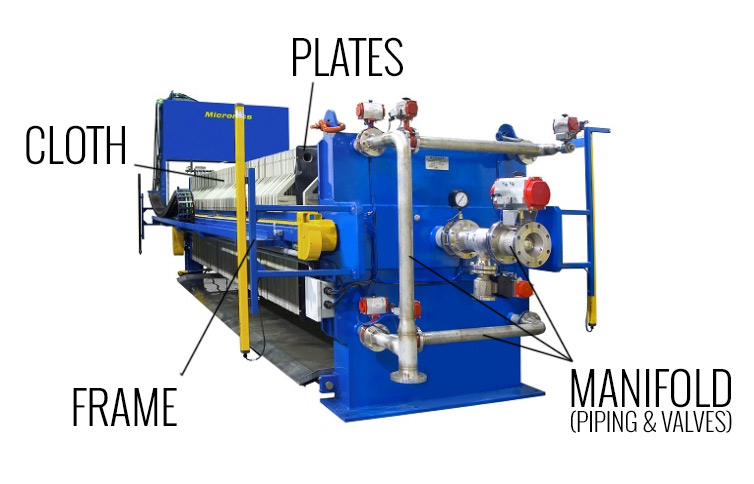

Filter presses comprise a set of chamber plates covered by filter clothes and squeezed by a hydraulic cylinder between a stationary frame and a mobile supporting beam.

Ilona schneider describes how to use filter sheets for wine filtration.

The plate filter has been designed for polishing and sterilising liquids of different kinds such as wine olive oil beer milk cosmetics essences for herbal preparations.

Filter presses also known as plate and frame have many benefits.

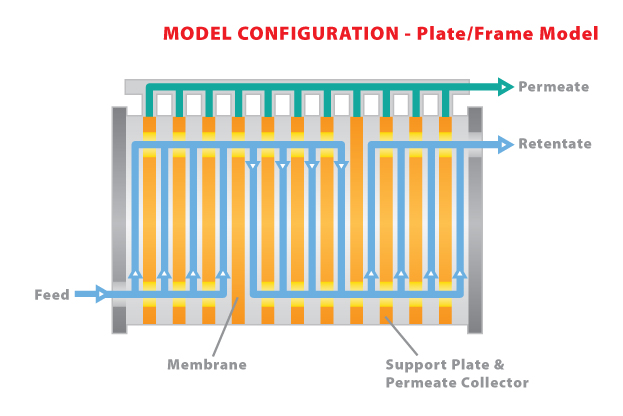

A plate and frame filter press is the most fundamental design and may be referred to as a membrane plate filter this type of filter press consists of many alternating plates and frames assembled with the supports of a pair of rails with filter membranes inserted between each plate frame pair.